Max. operating temp:150℃

Paired Flat Glass Insulated/Glass-braid Sheathed Extension and Compensating Cables for Thermocouples

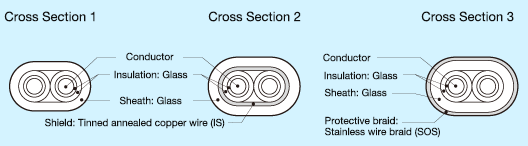

We provide paired flat extension and compensating cables for thermocouples, consisting of a pair of conductors glass-yarn served and insulated individually, and then glass-braid sheathed. As required, wire can be optionally shielded (to eliminate electrostatic induction interference) and/or protectively braided (to protect the wire surface from damage).

- Shield type

IS: Tinned-annealed-copper-wire braided shield TIS: Copper-tape shield AIS: Aluminum-polyester-tape shield containing drain wire - Protective braid type

SOS: Protective stainless-wire braid OS: Protective tinned-annealed-copper-wire braid

| Nominal cross-sectional area | Type | Cross Section | Conductor | Insulation | Pair | Shield | Protective braid | Sheath | Standard | Max length | Estimated weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Composition | Outside diameter | Thickness | Outside diameter | Outside diameter | Outside diameter | Thickness | Thickness | Outside diameter | |||||

| mm2 | Pcs/mm | mm | mm | mm | mm | mm | mm | mm | mm | m | kg/km | ||

| 0.3 | 12/0.18 x1P □-H-◇ |

1 | 12/0.18 | 0.7 | 0.4 | 1.5 | 1.5×3.0 | – | 0.3 | – | 2.1×3.6 | 1,000 | 13 |

| 0.3 | 12/0.18 x1P □-H-◇-IS |

2 | 12/0.18 | 0.7 | 0.4 | 1.5 | 1.5×3.0 | 0.3 | 0.3 | – | 2.7×4.2 | 1,000 | 24 |

| 0.3 | 12/0.18 x1P □-H-◇-SOS |

3 | 12/0.18 | 0.7 | 0.4 | 1.5 | 1.5×3.0 | – | 0.3 | 0.3 | 2.7×4.2 | 1,000 | 26 |

| 0.5 | 7/0.3 x1P □-H-◇ |

1 | 7/0.3 | 0.9 | 0.4 | 1.7 | 1.7×3.4 | – | 0.3 | – | 2.3×4.0 | 1,000 | 19 |

| 0.5 | 7/0.3 x1P □-H-◇-IS |

2 | 7/0.3 | 0.9 | 0.4 | 1.7 | 1.7×3.4 | 0.3 | 0.3 | – | 2.9×4.6 | 1,000 | 30 |

| 0.5 | 7/0.3 x1P □-H-◇-SOS |

3 | 7/0.3 | 0.9 | 0.4 | 1.7 | 1.7×3.4 | – | 0.3 | 0.3 | 2.9×4.6 | 1,000 | 32 |

| 0.5 | 20/0.18 x1P □-H-◇ |

1 | 20/0.18 | 1.0 | 0.4 | 1.8 | 1.8×3.6 | – | 0.3 | – | 2.4×4.2 | 1,000 | 22 |

| 0.5 | 20/0.18 x1P □-H-◇-IS |

2 | 20/0.18 | 1.0 | 0.4 | 1.8 | 1.8×3.6 | 0.3 | 0.3 | – | 3.0×4.8 | 1,000 | 31 |

| 0.5 | 20/0.18 x1P □-H-◇-SOS |

3 | 20/0.18 | 1.0 | 0.4 | 1.8 | 1.8×3.6 | – | 0.3 | 0.3 | 3.0×4.8 | 1,000 | 33 |

| 0.75 | 30/0.18 x1P □-H-◇ |

1 | 30/0.18 | 1.2 | 0.4 | 2.0 | 2.0×4.0 | – | 0.3 | – | 2.6×4.6 | 1,000 | 26 |

| 0.75 | 30/0.18 x1P □-H-◇-IS |

2 | 30/0.18 | 1.2 | 0.4 | 2.0 | 2.0×4.0 | 0.3 | 0.3 | – | 3.2×5.2 | 1,000 | 41 |

| 0.75 | 30/0.18 x1P □-H-◇-SOS |

3 | 30/0.18 | 1.2 | 0.4 | 2.0 | 2.0×4.0 | – | 0.3 | 0.3 | 3.2×5.2 | 1,000 | 42 |

| 1.25 | 7/0.45 x1P □-H-◇ |

1 | 7/0.45 | 1.35 | 0.4 | 2.15 | 2.15×4.3 | – | 0.35 | – | 2.9×5.0 | 1,000 | 36 |

| 1.25 | 7/0.45 x1P □-H-◇-IS |

2 | 7/0.45 | 1.35 | 0.4 | 2.15 | 2.15×4.3 | 0.3 | 0.35 | – | 3.5×5.6 | 1,000 | 50 |

| 1.25 | 7/0.45 x1P □-H-◇-SOS |

3 | 7/0.45 | 1.35 | 0.4 | 2.15 | 2.15×4.3 | – | 0.35 | 0.3 | 3.5×5.6 | 1,000 | 52 |

| 1.3 | 4/0.65 x1P □-H-◇ |

1 | 4/0.65 | 1.57 | 0.4 | 2.37 | 2.37×4.74 | – | 0.35 | – | 3.1×5.4 | 1,000 | 40 |

| 1.3 | 4/0.65 x1P □-H-◇-IS |

2 | 4/0.65 | 1.57 | 0.4 | 2.37 | 2.37×4.74 | 0.3 | 0.35 | – | 3.7×6.0 | 1,000 | 56 |

| 1.3 | 4/0.65 x1P □-H-◇-SOS |

3 | 4/0.65 | 1.57 | 0.4 | 2.37 | 2.37×4.74 | – | 0.35 | 0.3 | 3.7×6.0 | 1,000 | 57 |

| 2.3 | 7/0.65 x1P □-H-◇ |

1 | 7/0.65 | 1.95 | 0.4 | 2.75 | 2.75×5.5 | – | 0.35 | – | 3.5×6.2 | 1,000 | 60 |

| 2.3 | 7/0.65 x1P □-H-◇-IS |

2 | 7/0.65 | 1.95 | 0.4 | 2.75 | 2.75×5.5 | 0.3 | 0.35 | – | 4.1×6.8 | 1,000 | 77 |

| 2.3 | 7/0.65 x1P □-H-◇-SOS |

3 | 7/0.65 | 1.95 | 0.4 | 2.75 | 2.75×5.5 | – | 0.35 | 0.3 | 4.1×6.8 | 1,000 | 78 |

When placing an order, please replace each of the □ symbols with the type and tolerance class of the appropriate extension and compensating cable for thermocouples (see Table 1), and each of the ◇ symbols with its identification code (see Table 2).

In addition to paired cables, we can make multi-pair cables. Please consult us.

The estimated weights represent calculated values for reference purposes, which do not include the weight of the drum.

*Please feel free to contact our Sales Department for custom-made products not listed above.