Extension and Compensating Cables for Thermocouples

Extension and compensating cables for thermocouples are special-purpose lead wires for connecting thermocouples (thermometers) with measuring instruments.

Different types of cables are used for different types of thermocouples; their components, identification (color coding), compensation temperatures (connecting-point temperatures) at the point of contact with thermocouples, wire specification tolerances, and other requirements are defined by JIS.

In response to your requests, Ninomiya Electric Wire Co., Ltd., produces and provides a variety of precise, high-quality extension and compensating cables for thermocouples. In addition to the general characteristics of our products, our special cables, building on the features of our other products, can be used under severe conditions such as high temperatures and are well accepted in many areas. We also produce non-cataloged special products tailored to your requests.

Product Search

Extension and Compensating Cables for Thermocouples

Types/Identifications/Conductor Materials of Extension and Compensating Cables for Thermocouples

Ninomiya's extension and compensating cables for thermocouples comply with JIS C1610-2012, JIS C1610-1995 and ASTM E 230 (formerly ANSI MC 96.1).

| Thermocouple Types for Combined Use | Conductor Material | JIS C1610 | ASTM E 230 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| + | - | Type and Color of Extension and Compensating Cables for Thermocouples | Compensating contact temperature | Tolerance | Type and Color of Extension and Compensating Cables for Thermocouples | Compensating contact temperature | Tolerance | |||||||

| Type | 2012 (1995 classification 1) | Type | Former JIS Color (1995 classification 2) | ℃ | Class 1 (μV) | Class 2 (μV) | Type | Color Classification | ℃ | SPECIAL (℃) |

STANDARD (℃) |

|||

| B | Copper | Copper | BC |

|

BX |

|

0~+100 | No regulations | BX |

|

0~+200 | - | ±4.2 | |

| R | Copper | Copper nickel alloy | RCA |

|

RX |

|

0~+100 | - | ±30 | RX |

|

0~+200 | - | ±5.0 |

| Copper | Copper nickel alloy | RCB |

|

0~+200 | - | ±60 | ||||||||

| S | Copper | Copper nickel alloy | SCA |

|

SX |

|

0~+100 | - | ±30 | SX |

|

0~+200 | - | ±5.0 |

| Copper | Copper nickel alloy | SCB |

|

0~+200 | - | ±60 | ||||||||

| N | Nickel-chrome alloy | Nickel-silicon alloy | NX |

|

- | -25~+200 | ±60 | ±100 | NX |

|

0~+200 | ±1.1 | ±2.2 | |

| K | Nickel-chrome alloy | Nickel alloy | KX |

|

KX |

|

-25~+200 | ±60 | ±100 | KX |

|

0~+200 | ±1.1 | ±2.2 |

| Iron | Copper nickel alloy | KCA |

|

WX (KCB) |

|

0~+150 | - | ±100 | ||||||

| Copper | Copper nickel alloy | KCB |

|

VX (KCC) |

|

0~+100 | - | ±100 | ||||||

| E | Copper nickel-chrome alloy | Copper nickel alloy | EX |

|

EX |

|

-25~+200 | ±120 | ±200 | EX |

|

0~+200 | ±1.0 | ±1.7 |

| J | Iron | Copper nickel alloy | JX |

|

JX |

|

-25~+200 | ±85 | ±140 | JX |

|

0~+200 | ±1.1 | ±2.2 |

| T | Copper | Copper nickel alloy | TX |

|

TX |

|

-25~+100 | ±30 | ±60 | TX |

|

-60~+100 | ±0.5 | ±1.0 |

Selection of Extension and Compensating Cables for Thermocouples Combined with K Thermocouple

There are the following three types: KX (high precision); KCA [WX] (for heat resistance); and KCB [VX] (for general use)

When selecting, consider the ambient temperature to be used and the required accuracy.

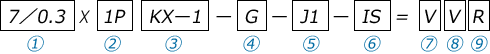

How to Place an Order and Apply Symbols

How to Place an Order and Apply Symbols

- (1) Conductor Configuration (see each product page)

- Select the conductor size.

- (2) The Number of Pairs

- One pair (1P) refers to 2 core wires. For a extension and compensating cables for thermocouples, a plus and a minus are usually used as a pair.

- (3) Types and Tolerance Classes of Extension and Compensating Cables for Thermocouples (see Table 1 below)

- The extension and compensating cables for thermocouples must be the same as the thermocouple used in combination.

- (4) Application Classification

- Select the insulator and sheath material to be used for the conductor.

- (5) Identification (see Table 2 below2)

- Identification should be done according to the insulator and the sheath color.

- (6) Shielding and Protection Braid

- Specify the shielding and protection braid as needed.

- (7)(8) Insulator and Sheath Material

- As a standard, the same material is used for both insulator and sheath. However, different materials can be used in combination, depending on the intended use. Select the most suitable coating material according to the service conditions and applications.

- (9) Shape

- F: Flat

R: Round (Interposed)

T: Round (not interposed)

P: Flat with a protection braid with no sheath

FF: Flat - spectacle shape

r: Flat - tenioid

Table 1 Types and Tolerance Classes of Extension and Compensating Cables for Thermocouples (type to be inserted in □)

| Item | Symbol | Tolerance class | ||

|---|---|---|---|---|

| JIS | ASTM | JIS | ASTM | |

| Extension and Compensating Cables for Thermocouples Type Tolerance class |

BC | BX-ASt | Not specified | Standard |

| RCA-2 | RX-ASt | Class 2 | Standard | |

| RCB-2 | Class 2 | |||

| SCA-2 | SX-ASt | Class 2 | Standard | |

| SCB-2 | Class 2 | |||

| NX-1 | NX-ASp | Class 1 | Special | |

| NX-2 | NX-ASt | Class 2 | Standard | |

| KX-1 | KX-ASp | Class 1 | Special | |

| KX-2 | KX-ASt | Class 2 | Standard | |

| KCA-2(WX) | - | Class 2 | - | |

| KCB-2(VX) | - | Class 2 | - | |

| EX-1 | EX-ASp | Class 1 | Special | |

| EX-2 | EX-ASt | Class 2 | Standard | |

| JX-1 | JX-ASp | Class 1 | Special | |

| JX-2 | JX-ASt | Class 2 | Standard | |

| TX-1 | TX-ASp | Class 1 | Special | |

| TX-2 | TX-ASt | Class 2 | Standard | |

Table 2 Identification (symbol to be inserted in ◇)

| Item | Symbol | Tolerance class |

|---|---|---|

| Identification | J1 | Color code for JIS classification 1 |

| J2 | Color code for JIS classification 2 | |

| AS | Color code for ASTM (formerly ANSI MC96.1) |

List of reciprocating conductor resistances of extension

List of reciprocating conductor resistances of extension and compensating cables for thermocouples on a size-by-size basis (reference values at 20°C/standard)

| JIS C 1610-2012 | BC | RCA/RCB | SCA/SCB | NX | KX | KCA | KCB | EX | JX | TX | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JIS C 1610-1981 | BX | RX | SX | - | KX | WX | VX | EX | JX | TX | |

| Nominal cross-sectional area mm2 |

Composition Pcs/mm |

Reciprocating conductor resistance Ω/m |

|||||||||

| 0.3 | 12/0.18 | 0.12 | 0.28 | 0.28 | 5.0 | 3.6 | 2.5 | 2.1 | 4.5 | 2.5 | 2.1 |

| 0.5 | 7/0.3 | 0.08 | 0.17 | 0.17 | 3.0 | 2.2 | 1.4 | 1.2 | 2.7 | 1.4 | 1.2 |

| 20/0.18 | 0.08 | 0.17 | 0.17 | 3.0 | 2.2 | 1.4 | 1.2 | 2.7 | 1.4 | 1.2 | |

| 0.75 | 30/0.18 | 0.05 | 0.11 | 0.11 | 2.0 | 1.5 | 0.95 | 0.75 | 1.8 | 0.95 | 0.75 |

| 1.25 | 7/0.45 | 0.04 | 0.080 | 0.080 | 1.3 | 1.0 | 0.65 | 0.55 | 1.3 | 0.65 | 0.55 |

| 50/0.18 | 0.04 | 0.080 | 0.080 | 1.3 | 1.0 | 0.65 | 0.55 | 1.3 | 0.65 | 0.55 | |

| 1.3 | 4/0.65 | 0.03 | 0.070 | 0.070 | 1.1 | 0.90 | 0.55 | 0.45 | 1.1 | 0.55 | 0.45 |

| 2.3 | 7/0.65 | 0.02 | 0.040 | 0.040 | 0.65 | 0.50 | 0.30 | 0.25 | 0.60 | 0.30 | 0.25 |

List of thermal electromotive forces of extension

| Type | Electromotive force (µV) | Tolerance | |||

|---|---|---|---|---|---|

| 0℃ | 100℃ | 200℃ | (μV) | (℃) | |

| RCA(RX-G) | 0 | 647 | - | ±30 | ±4.0 |

| RCB(RX-H) | 0 | 647 | 1469 | ±60 | ±7.0 |

| SCA | 0 | 646 | - | ±30 | ±4.0 |

| SCB | 0 | 646 | 1441 | ±60 | ±7.0 |

| NX Class 1 | 0 | 2774 | 5913 | ±60 | ±2.0 |

| NX Class 2 | 0 | 2774 | 5913 | ±100 | ±3.4 |

| KX Class 1 | 0 | 4096 | 8138 | ±60 | ±1.5 |

| KX Class 2 | 0 | 4096 | 8138 | ±100 | ±2.5 |

| KCA(WX) | 0 | 4096 | - | ±100 | ±2.5 |

| KCB(VX) | 0 | 4096 | - | ±100 | ±2.5 |

| EX Class 1 | 0 | 6319 | 13421 | ±120 | ±1.5 |

| EX Class 2 | 0 | 6319 | 13421 | ±200 | ±2.5 |

| JX Class 1 | 0 | 5269 | 10779 | ±85 | ±1.5 |

| JX Class 2 | 0 | 5269 | 10779 | ±140 | ±2.5 |

| TX Class 1 | 0 | 4279 | - | ±30 | ±0.5 |

| TX Class 2 | 0 | 4279 | - | ±60 | ±1.0 |