Duplex PEEK Insulated Thermocouple Wire

We provide flat duplex insulated thermocouple wire consisting of a pair of conductors individually PEEK-resin insulated, and then PEEK-resin sheathed. PEEK resin is an insulating material that exhibits excellent properties, including no halogen content, low outgassing, a high melting point, and a high radiation resistance.

Product Features

- Features of PEEK resin

No halogen content, low outgassing

low elution, low toxic-gas content

High heat resistance (260℃), high melting point (340℃) *The heat distortion temperature is 1.5 times higher than that of PTEF.

flame resistance (UL94-V0 certified without adding a flame retardant)

radiation resistance, and high sliding performance - Lineup

In response to the needs of many of our customers, we provide Types K and T, with 0.32-mm and 0.65-mm conductors, respectively. We can also make products compliant with Class 1. Please specify when placing an order. - List of main products

Type-K duplex insulated thermocouple wire

0.32 x1P K-2-PEEK-J1

0.65 x1P K-2-PEEK-J1 Type-T duplex insulated thermocouple wire

0.32 x1P T-2-PEEK-J1

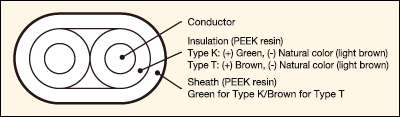

0.65 x1P T-2-PEEK-J1 - Structure

At your request, we perform end welding, molding, and terminal treatment.

We can also make PEEK insulated, heat-resistant wire. Please feel free to contact us.

We can also make PEEK insulated, heat-resistant wire. Please feel free to contact us.

Materials and Compositions

Type K

| Attribute | Unit | Specifications/composition | Material/remarks | |||

|---|---|---|---|---|---|---|

| Conductor | Surface treatment | – | No treatment |

Positive side: Nickel chrome alloy

Negative side: Nickel alloy |

||

| Composition | Pcs/mm | 1/0.32 | 1/0.65 | |||

| Outside diameter | mm | Approx. 0.32 | Approx. 0.65 | |||

| Insulation | Thickness | mm | Approx. 0.15 | Approx. 0.15 | PEEK resin | |

| Outside diameter | mm | Approx. 0.62 | Approx. 0.95 | |||

| Identification | – | (+) Green, (-) Natural color (light brown) | ||||

| Parallel two-conductor outside diameter | mm | Approx. 0.6×1.2 | Approx. 1.0×1.9 | |||

| Sheath | Thickness | mm | Approx. 0.15 | Approx. 0.15 | PEEK resin | |

| Outside diameter | mm | Approx. 0.9×1.5 | Approx. 1.3×2.2 | |||

| Identification | – | Green | JIS C 1610 2012 8.6.1, Table 9 |

|||

| Standard overall diameter | mm | Approx. 0.9×1.5 | Approx. 1.3×2.2 | |||

| Electrical Characteristics | Reciprocating conductor resistance (20℃, standard) |

Ω/m | 12.1 | 2.92 | JIS C 3005 4.4 | |

| Insulation resistance (20℃, minimum) |

MΩ・km | 500 | JIS C 3005 4.7 | |||

| Tolerance | From -40℃ to less than +333℃ | ℃ | ±2.5 | JIS C 1602 K Class 2 t represents the measured temperature. |

||

| From 333℃ to less than 1200℃ | ℃ | 0.0075×|t| | ||||

| Standard thermal electromotive force at 100°C | μV | 4096 | Appended Table 5 of JIS C 1602 | |||

| Withstand voltage (AC/sparks) | V | 3000 | Insulation only JIS C 3005 4.6 |

|||

| Electromotive force inspection temperature | ℃ | 100 | ||||

| Normal-use temperature limit for thermocouple component wire | ℃ | 400 | 650 | |||

| Overheating temperature limit for thermocouple component wire | ℃ | 500 | 850 | |||

| Continuous use temperature for sheath materials | ℃ | -45 ~ +260 | ||||

| Estimated weight | kg/km | 3 | 9 | |||

* The test method for electrical characteristics is per JIS 3005.

Type T

| Attribute | Unit | Specifications/composition | Material/remarks | |||

|---|---|---|---|---|---|---|

| Conductor | Surface treatment | ー | No treatment |

Positive side: Nickel chrome alloy

Negative side: Nickel alloy |

||

| Composition | Pcs/mm | 1/0.32 | 1/0.65 | |||

| Outside diameter | mm | Approx. 0.32 | Approx. 0.65 | |||

| Insulation | Thickness | mm | Approx. 0.15 | Approx. 0.15 | PEEK resin | |

| Outside diameter | mm | Approx. 0.62 | Approx. 0.95 | |||

| Identification | ー | (+) Green, (-) Natural color (light brown) | ||||

| Parallel two-conductor outside diameter | mm | Approx. 0.6×1.2 | Approx. 1.0×1.9 | |||

| Sheath | Thickness | mm | Approx. 0.15 | Approx. 0.15 | PEEK resin | |

| Outside diameter | mm | Approx. 0.9×1.5 | Approx. 1.3×2.2 | |||

| Identification | ー | Brown | JIS C 1610 2012 8.6.1, Table 9 |

|||

| Standard overall diameter | mm | 約 0.9×1.5 | 約 1.3×2.2 | |||

| Electrical Characteristics | Reciprocating conductor resistance (20℃, standard) |

Ω/m | 6.17 | 1.50 | JIS C 3005 4.4 | |

| Insulation resistance (20℃, minimum) |

MΩ・km | 500 | JIS C 3005 4.7 | |||

| Tolerance | From -40℃ to less than +333℃ | ℃ | ±1 | JIS C 1602 K Class 2 t represents the measured temperature. |

||

| From 333℃ to less than 1200℃ | ℃ | 0.0075×|t| | ||||

| Standard thermal electromotive force at 100°C | μV | 4279 | Appended Table 5 of JIS C 1602 | |||

| Withstand voltage (AC/sparks) | V | 3000 | Insulation only JIS C 3005 4.6 |

|||

| Electromotive force inspection temperature | ℃ | 100 | ||||

| Normal-use temperature limit for thermocouple component wire | ℃ | 200 | 200 | |||

| Overheating temperature limit for thermocouple component wire | ℃ | 250 | 250 | |||

| Continuous use temperature for sheath materials | ℃ | -45 ~ +260 | ||||

| Estimated weight | kg/km | 3 | 9 | |||

* The test method for electrical characteristics is per JIS 3005.