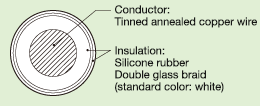

Silicone-rubber Insulated Glass-yarn Braided Wire: LKGB/SRDGB

Max. operating temp:180℃

The LKGB, SRDGB15, SRDGB33, and SRDGB66 series offer glass-yarn braided wire that is mechanically stronger than silicone-rubber insulated wire.

The rated voltages available are 600 V, 1,500 V, 3,300 V, and 6,600 V.

The LKGB series offers PSE products standardized according to Electrical Appliances and Material Safety Act. SRGB15 series products are standardized by Ninomiya Electric Wire. The SRDGB33 and SRDGB66 series offer JIS C-3315 compliant products standardized by Ninomiya Electric Wire.

Applications

- LKGB/SRDGB series wire is used for applications such as wire used in general high-temperature parts with temperatures up to 180℃, generators, and motors, and lead wire for electrical equipment.

* The standard identification color is white. We can also use black, red, green, yellow, brown, blue, gray, and other colors at your request.

* For the SRDGB series, we can use nickel or other material as the conductor at your request.

* We can also produce silicone-rubber insulated wire for sensors, multi-conductor products with more than two conductors, shielded wire, and more.

Lineup

| Product Name (Rated voltage) |

Nominal cross-sectional area m㎡ |

Conductor | Insulation thickness mm |

Braid thickness mm |

Standard overall diameter mm |

Conductor resistance (20℃, standard) Ω/km |

Insulation resistance (20℃, minimum) MΩ・km |

Test voltage (AC, 1 min.) V |

Estimated weight kg/k |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Composition Pcs/mm |

Outside diameter mm |

|||||||||

| LKGB (600V) <PSE> |

0.75 | 30/0.18 | 1.1 | 1.1 | 0.5 | 4.4 | 25.8 | 100 | 1500 | 30 |

| 1.25 | 50/0.18 | 1.5 | 1.1 | 0.5 | 4.7 | 15.5 | 100 | 1500 | 40 | |

| 2 | 37/0.26 | 1.8 | 1.1 | 0.5 | 5.0 | 9.91 | 100 | 1500 | 50 | |

| 3.5 | 45/0.32 | 2.4 | 1.1 | 0.5 | 5.7 | 5.38 | 100 | 1500 | 70 | |

| 5.5 | 35/0.45 | 3.1 | 1.1 | 0.5 | 6.3 | 3.50 | 90 | 1500 | 90 | |

| 8 | 50/0.45 | 3.7 | 1.1 | 0.5 | 6.9 | 2.45 | 80 | 1500 | 120 | |

| 14 | 88/0.45 | 4.9 | 1.1 | 0.6 | 8.3 | 1.39 | 60 | 2000 | 200 | |

| 22 | 7/20/0.45 | 7.0 | 1.4 | 0.6 | 11.0 | 0.892 | 70 | 2000 | 310 | |

| 38 | 7/34/0.45 | 9.1 | 1.4 | 0.6 | 13.1 | 0.525 | 50 | 2500 | 520 | |

| 60 | 19/20/0.45 | 11.6 | 1.8 | 0.6 | 16.2 | 0.329 | 50 | 2500 | 750 | |

| 100 | 19/24/0.45 | 15.2 | 2.3 | 0.7 | 21.2 | 0.193 | 50 | 2500 | 1270 | |

| SRDGB15 (1500V) |

2 | 37/0.26 | 1.8 | 2.0 | 0.5 | 6.8 | 9.91 | 150 | 5000 | 70 |

| 3.5 | 45/0.32 | 2.4 | 2.0 | 0.5 | 7.5 | 5.38 | 100 | 5000 | 100 | |

| 5.5 | 35/0.45 | 3.1 | 2.0 | 0.5 | 8.1 | 3.50 | 100 | 5000 | 120 | |

| 8 | 50/0.45 | 3.7 | 2.0 | 0.5 | 8.9 | 2.45 | 100 | 5000 | 160 | |

| 14 | 88/0.45 | 4.9 | 2.5 | 0.6 | 11.1 | 1.39 | 100 | 5000 | 250 | |

| 22 | 7/20/0.45 | 7.0 | 2.5 | 0.6 | 13.2 | 0.892 | 80 | 5000 | 380 | |

| 38 | 7/34/0.45 | 9.1 | 2.5 | 0.6 | 15. | 0.525 | 60 | 5000 | 560 | |

| 60 | 19/20/0.45 | 11.6 | 2.5 | 0.6 | 18.0 | 0.329 | 50 | 5000 | 820 | |

| SRDGB33 (3300V) |

8 | 50/0.45 | 3.7 | 3.0 | 0.6 | 10.9 | 2.45 | 150 | 8000 | 200 |

| 14 | 88/0.45 | 4.9 | 3.0 | 0.6 | 12.1 | 1.39 | 150 | 8000 | 280 | |

| 22 | 7/20/0.45 | 7.0 | 3.0 | 0.6 | 14.2 | 0.892 | 100 | 8000 | 410 | |

| 38 | 7/34/0.45 | 9.1 | 3.0 | 0.6 | 16.3 | 0.525 | 80 | 8000 | 600 | |

| 60 | 19/20/0.45 | 11.6 | 3.5 | 0.7 | 20.0 | 0.329 | 70 | 8000 | 910 | |

| SRDGB66 (6600V) |

8 | 50/0.45 | 3.7 | 5.0 | 0.6 | 14.9 | 2.45 | 200 | 15000 | 300 |

| 14 | 88/0.45 | 4.9 | 5.0 | 0.6 | 16.1 | 1.39 | 200 | 15000 | 390 | |

| 22 | 7/20/0.45 | 7.0 | 5.0 | 0.7 | 18.4 | 0.892 | 150 | 15000 | 520 | |

| 38 | 7/34/045 | 9.1 | 5.0 | 0.7 | 20.5 | 0.525 | 100 | 15000 | 740 | |

*Please feel free to contact our Sales Department for custom-made products not listed above.

* These products are not designed to withstand the usage that requires flex resistance.

List of allowable current values

| Product Name | Size | Ambient temperature | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50℃ | 60℃ | 70℃ | 80℃ | 90℃ | 100℃ | 110℃ | 120℃ | 130℃ | 140℃ | 150℃ | 160℃ | 170℃ | ||

| LKGB | 0.75SQ | 29 | 28 | 26 | 25 | 24 | 23 | 21 | 19 | 18 | 16 | 14 | 11 | 8 |

| 1.25SQ | 39 | 38 | 36 | 34 | 33 | 31 | 29 | 26 | 24 | 22 | 19 | 15 | 11 | |

| 2SQ | 56 | 54 | 51 | 49 | 46 | 44 | 41 | 38 | 35 | 31 | 27 | 22 | 15 | |

| 3.5SQ | 77 | 74 | 70 | 67 | 64 | 60 | 56 | 52 | 47 | 42 | 37 | 30 | 21 | |

| 5.5SQ | 102 | 98 | 93 | 89 | 84 | 80 | 75 | 69 | 63 | 56 | 49 | 40 | 28 | |

| 8SQ | 127 | 122 | 116 | 111 | 105 | 99 | 93 | 86 | 78 | 70 | 61 | 50 | 35 | |

| 14SQ | 183 | 176 | 168 | 161 | 152 | 143 | 134 | 124 | 113 | 101 | 88 | 72 | 51 | |

| 22SQ | 239 | 230 | 219 | 210 | 199 | 187 | 176 | 162 | 148 | 132 | 115 | 94 | 66 | |

| 38SQ | 337 | 324 | 309 | 296 | 280 | 264 | 248 | 228 | 209 | 186 | 162 | 133 | 94 | |

| 60SQ | 451 | 434 | 414 | 397 | 375 | 353 | 332 | 306 | 280 | 249 | 217 | 178 | 126 | |

| 100SQ | 620 | 596 | 569 | 545 | 515 | 485 | 456 | 420 | 384 | 342 | 298 | 244 | 173 | |

*The above allowable current values are the values calculated based on the assumption that the products are used in a normal open atmosphere.

Please use LKGB/SRDGB series products with a safety current that ensures safe operation.

*For SR and LKGB series products, the indicated allowable current values are for the insulated wires defined in Article 29 of the guide book of electrical equipment.

*SRDGB series products are manufactured based on the Standards of Ninomiya Electric Wire Co., Ltd.