Glass-yarn braided Wire: GB

Max. operating temp:180℃

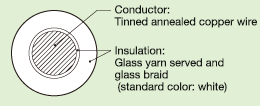

Glass-yarn braided wire (GB) is the most common heat-resistant insulated wire. It is made of tinned annealed copper wire coated with glass fiber. GB is manufactured according to the NINOMIYA Standards.

Applications

Since GB is a low-cost heat-resistant insulated wire, it is used for applications such as the lead wire of an electric heater and the wire used in general high-temperature parts with temperatures up to 180℃.

Lineup

| Nominal cross-sectional area m㎡ |

Conductor | Insulation thickness mm |

Braid thickness mm |

Standard overall diameter mm |

Conductor resistance (20℃, standard) Ω/km |

Insulation resistance (20℃, minimum) MΩ・km |

Test voltage (AC, 1 min.) V |

Estimated weight kg/k |

|

|---|---|---|---|---|---|---|---|---|---|

| Composition Pcs/mm |

Outside diameter mm |

||||||||

| 0.5 | 20/0.18 | 0.9 | 0.15 | 0.3 | 1.9 | 38.6 | 1.0 | 600 | 9 |

| 0.75 | 30/0.18 | 1.1 | 0.15 | 0.3 | 2.1 | 25.8 | 1.0 | 600 | 12 |

| 1.25 | 50/0.18 | 1.5 | 0.15 | 0.35 | 2.5 | 15.5 | 1.0 | 600 | 18 |

| 2.0 | 37/0.26 | 1.8 | 0.15 | 0.35 | 2.8 | 9.91 | 1.0 | 600 | 25 |

| 3.5 | 45/0.32 | 2.4 | 0.15 | 0.35 | 3.5 | 5.38 | 1.0 | 600 | 43 |

| 5.5 | 35/0.45 | 3.1 | 0.15 | 0.35 | 4.1 | 3.50 | 1.0 | 600 | 62 |

| 8 | 50/0.45 | 3.7 | – | 0.6 | 4.9 | 2.45 | 1.0 | 600 | 87 |

| 14 | 88/0.45 | 4.9 | – | 0.6 | 6.1 | 1.39 | 1.0 | 600 | 145 |

| 22 | 7/20/0.45 | 7.0 | – | 0.6 | 8.2 | 0.892 | 1.0 | 600 | 230 |

*Since GB series products have hygroscopicity, their insulating characteristics greatly differ depending on the atmosphere in which each of them is routed. Therefore, avoid using GB series products in humid or wet places. Please feel free to contact our Sales Department for custom-made products not listed above.

List of allowable current values

| Size | Ambient temperature | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50℃ | 60℃ | 70℃ | 80℃ | 90℃ | 100℃ | 110℃ | 120℃ | 130℃ | 140℃ | 150℃ | 160℃ | 170℃ | |

| 0.5SQ | 21.1 | 20.2 | 19.4 | 18.3 | 17.4 | 16.5 | 15.5 | 14.2 | 13.0 | 11.6 | 9.9 | 8.1 | 5.2 |

| 0.75SQ | 26.6 | 25.5 | 24.6 | 23.4 | 22.1 | 21.0 | 19.7 | 18.2 | 16.5 | 14.7 | 12.7 | 10.2 | 6.9 |

| 1.25SQ | 36.9 | 35.3 | 34.0 | 32.6 | 30.9 | 29.1 | 27.4 | 25.3 | 23.1 | 20.5 | 17.7 | 14.2 | 9.6 |

| 2SQ | 47.6 | 46.1 | 44.2 | 42.3 | 40.3 | 37.8 | 25.5 | 33.1 | 29.9 | 27.0 | 23.0 | 18.2 | 12.9 |

| 3.5SQ | 70.5 | 67.6 | 65.2 | 62.1 | 59.4 | 55.9 | 52.2 | 48.2 | 43.9 | 39.0 | 33.5 | 26.9 | 17.9 |

| 5.5SQ | 92.5 | 89.5 | 85.2 | 82.2 | 78.5 | 73.5 | 69.3 | 63.7 | 58.8 | 52.0 | 45.8 | 36.8 | 24.5 |

| 8SQ | 117 | 112 | 108 | 103 | 98.5 | 93.0 | 87.2 | 80.9 | 74.1 | 66.6 | 58.1 | 45.9 | 32.5 |

| 14SQ | 167 | 162 | 156 | 149 | 141 | 134 | 127 | 117 | 107 | 95.2 | 81.7 | 65.5 | 43.7 |

| 22SQ | 233 | 226 | 217 | 207 | 197 | 187 | 175 | 163 | 150 | 136 | 115 | 96.2 | 64.1 |

*The above allowable current values are the values calculated based on the assumption that the products are used in a normal open atmosphere.

Please use GB series products with a safety current that ensures safe operation.

*The above allowable current values of GB series products are the reference values calculated based on our demonstration experiments.

*GB series products are manufactured based on the Standards of Ninomiya Electric Wire Co., Ltd.