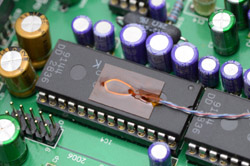

Thin-film Surface Thermocouple (seal type)

NSH / NSMH:200℃

製品特徴

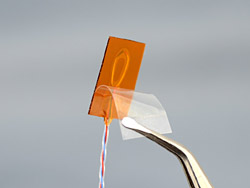

It’s easy to affix. Simply peel off the separator sheet. Because the separator is larger than the sheet body, it’s easy to peel off.

- Type

Type K thermocouple

Sheet size: Choose from two sizes of standard and miniature.

Type T thermocouple

Sheet size: Only miniature size is available. - Heatproof Temperature

For general use: Up to 200°C

(The lead wire’s max. operating temperature is 260°C.) The product has almost no outgassing. - Because one end of the coated thermocouple wire with the optimum usable length is set as the hot junction, there’s no need to prepare a lead wire separately.

- The coated thermocouple wire, with PFA fluororesin as an insulator, has the heat resistance of 260°C and excellent chemical resistance. The twisted pair structure can also reduce the noise caused by electromagnetic induction.

- We can accommodate customer needs in terminal processing with one side exposed, with a thermocouple connector (our Twintor product), and with a Y terminal. Terminal processing that doesn’t insulate the hot junction is also available.

Product cut samples can be provided.

For the request for samples, please contact us from hre. Person in charge: Ohashi (Sales Dept., Head Office)

Product Schematic Diagram

Product Specifications

| Type K thermocouple | Type T thermocouple | ||

|---|---|---|---|

| For General Use | For General Use | ||

| Standard | Miniature | Miniature | |

| Sheet size | Approx. 20 x 10 | Approx. 14 x 10 | Approx. 14 x 10 |

| Sheet thickness | Approx. 0.35 | <- | <- |

| Lead wire dia. | 0.2 | <- | <- |

| Lead wire finished outer dia. | Approx. 0.9 | <- | <- |

| Lead wire length | Specified length | <- | <- |

| Measured temperature | 200℃ | <- | <- |

Unit = mm

* Max. operating temp. of lead area: 260°C

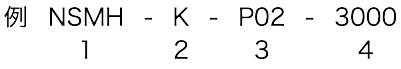

How to Apply Product Symbols

-

Select the grade/sheet size

NSH: Standard size for general use

NSMH: Miniature size for general use -

Select the thermocouple type

K: Type K thermocouple

T: Type T thermocouple (NSMH only) -

Select the terminal processing method

N: Cut off and no processing afterward

M: Exposed

Y: With Y terminal (M4)

P02: With thermocouple connector (miniature plug) -

Lead wire length

Please specify the desired length. (Unit: mm)

Please see the table below for the detailed specifications of the lead wires.

Lead Wire Specifications

| Item | Unit | Standards/structure | Material/remarks | |||

|---|---|---|---|---|---|---|

| Type K thermocouple | Type T thermocouple | |||||

| Conductor | Surface processing | – | DF processing | – | ||

| Material | + Side | Nickel-chromium alloy | Copper | |||

| – Side | Nickel alloy | Copper-nickel alloy | ||||

| Structure | Number of wires/mm | 1/0.2 | 1/0.2 | |||

| Outer diameter | mm | Approx. 0.2 | Approx. 0.2 | |||

| Conductor | Thickness | mm | Approx. 0.05 | Approx. 0.05 | Fluororesin PFA |

|

| Outer dia. | mm | Approx. 0.3 | Approx. 0.3 | |||

| Identification: | – | (+) Red (−) Blue | (+) Red (−) Brown | |||

| Twisted pair | 2-core twisted | mm | Approx. 0.6 | Approx. 0.6 | ||

| Sheath | Thickness | mm | Approx. 0.15 | Approx. 0.15 | Fluororesin PFA |

|

| Outer Diameter | mm | Approx. 0.9 | Approx. 0.9 | |||

| Identification | – | Transparent | Transparent | |||

| Finished Outer Diameter | mm | Approx. 0.9 | Approx. 0.9 | |||

| Electrical properties | Go-and-Return Conductor Resistance (20°C, Standard) | Ω/m | 31.5 | 16.5 | JIS C 1610 | |

| Insulation Resistance (20°C, minimum) | MΩ・km | 1000 | 1000 | |||

| Tolerance Interval | −40°C and higher, lower than +333°C | ℃ | ±2.5 | ー | ||

| −40°C and higher, lower than +133°C | ℃ | ー | ±1 | |||

| 333°C and higher, lower than 1200°C | ℃ | 0.0075×|t| | ー | |||

| 133°C and higher, lower than 350°C | ℃ | ー | 0.0075×|t| | |||

| Standard Thermo-electromotive Force at 100°C | μV | 4096 | 4279 | JIS C 1602 | ||

* Please contact our sales department for product specifications, ordering methods and technical details.

Adhesive Strength

| Initial Value | 180℃ | 200℃ | |

|---|---|---|---|

| Adhesive Strength (N/10 mm) | 5.10 | 6.54 | 6.85 |

| Rate of Change (VS Initial Value) | ー | 128% | 134% |

| Rate of Change (VS180°C) | ー | ー | 105% |

* The test was conducted internally using JIS Z 0237 as reference. The sample used was a single tape.

* The initial value was obtained after leaving the sample at room temperature for at least 2 hours after affixation. The heating condition: after applying heat for 1 hour, left at room temperature for 1 hour. The value is the average of n = 3.

* These values are strictly experimental values and not guaranteed values. They vary depending on each user’s purpose and method of use.

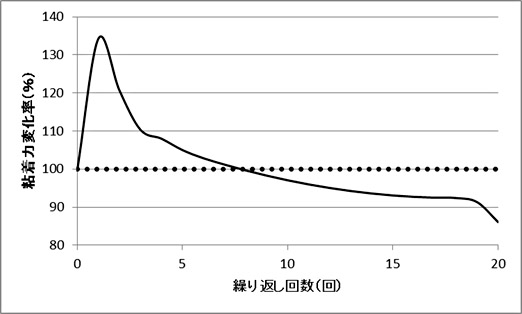

Durability Against Repetitive Affixation

* The test method undertaken was as follows: the adhesive strength of the same sample used in the adhesive strength test was measured repeatedly at the cycle of 1 hour of heating at 200°C and 1 hour of cooling. The maximum number of repetitions of this cycle was set to 20 times. The value is the average of n = 3.

* The figure shows the rate of change in the adhesive strength of repeated affixations, showing the transition when the initial value (0th time) was set to 100%.

* These values are strictly experimental values under the test environment and not guaranteed values. They vary depending on each user’s purpose and method of use.

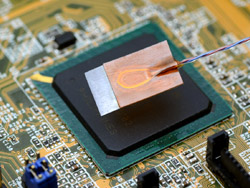

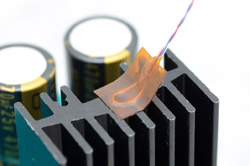

Application Examples

* A discrepancy in the measured temperature may occur, depending on how the product is affixed.